My Windows PC hardware is becoming quite venerable. Back in April 2016, just before I left work I purchased a HP Pavilion 550 which had a reasonable specification: I5 processor, 128GB SSD and 2TB hard drive, 8GB RAM and Window 10.

It broke down after 4.5 years in December 2020 and I considered upgrading, but honestly there was nothing better to spend my money on. Instead I purchased a re-conditioned HP 800 G1 desktop with a very similar specification for £200. The HP 800 G1 first became available in 2014 so it now about 10 years old.

Back in the olden days it was necessary to buy a new PC every couple of years and my bench mark was to spend £1,000. As Windows and software products increased their processing requirements a computer would soon begin to feel sluggish and need replacing. Clearly this is no longer true as both my existing and previous computers date from about 2015 and aren't lacking in specification. In fact both the HP Pavilion and 800 G1 are still available to purchase refurbished on eBay for around £60.

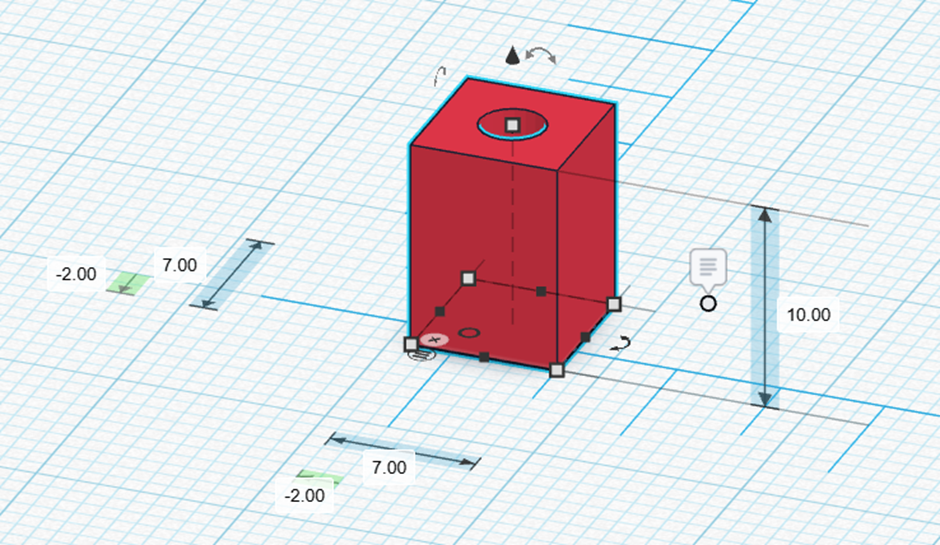

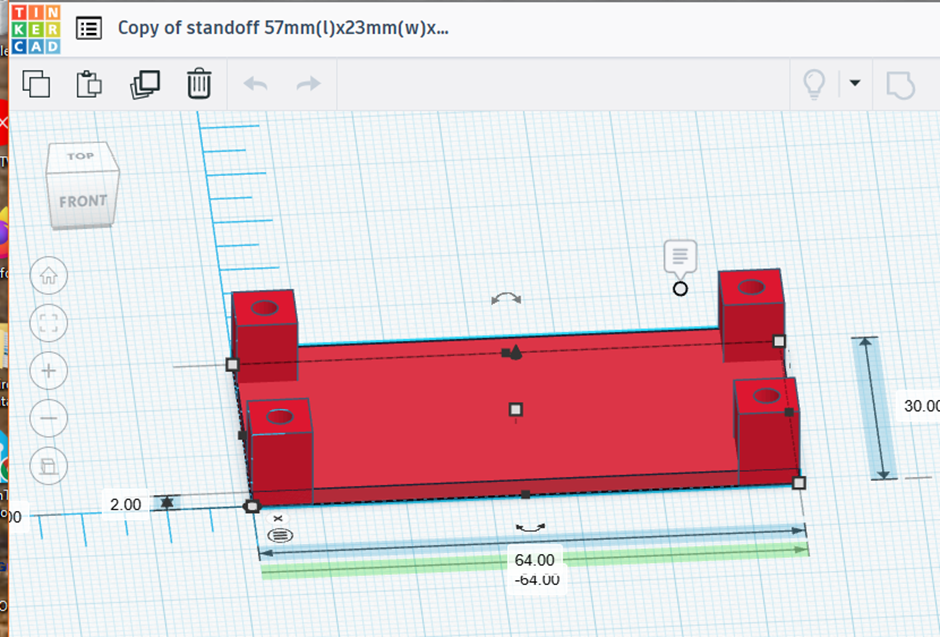

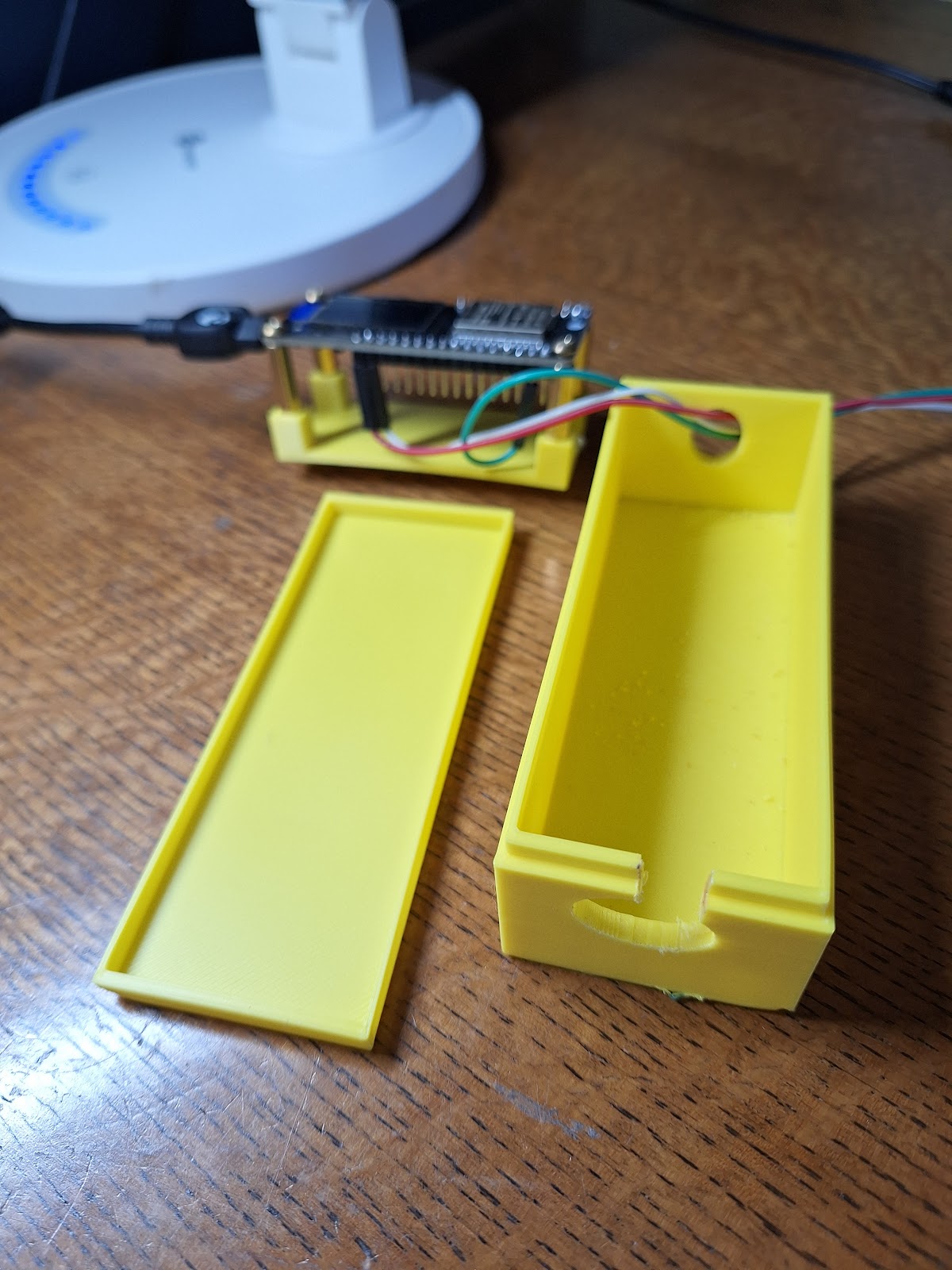

Over that time period processors have not become significantly faster, instead they have many more cores/threads and can handle more simultaneous activities but I believe, for most people, that isn't really necessary. For me there are only a few areas which feel slow: compiling FPGA images (Quartus), compiling guest Operating systems (linux guests) and 3D modelling software (Autodesk).

The two hardware factors which do make a difference are SSDs and memory capacity. An SSD for the C: drive is vital to prevent the OS chuntering away for ages. Plenty of memory needs to be available as applications (particularly chrome) gobble it up and it is usually best to keep many apps loaded.

Both these PCs run Windows 10 and neither of them has the TPM 2.0 hardware required to run Windows 11. As yet there is nothing in Windows 11 that I might need to use.

Windows 10 support, including security fixes is supposed to be terminated in 2025 as Microsoft try to force people to upgrade their PC and OS. You would have thought that after 10 years there are no more bugs to discover but I guess there are!

The title of this post is "EOL kicker" and the reason for this is C: drive space. Previous PCs have 128GB SSD C: drives which seems quite a lot. However, software tends to be installed on C and uses it for data storage. Over time I have tried to move files to D wherever possible and each time C fills up I look for more opportunities.

However, I finally gave up looking for more ways to save space and purchased a Crucial 256GB SSD for the princely sum of £16. I have used Crucial drives before and really like the software and instructions to copy and replace a system drive. It only takes a few minutes work and an hours copying time.

I hope / believe my problems are now over, at least until we see what happens in October as millions of people moan at Microsoft. In fact I have a little sympathy for Microsoft in this respect, they have done a good job keeping the software working for ten years - without me (and others) providing extra revenue by upgrading our systems.